How are masks and filter media tested?

Masks and Filter Media are tested using an Aerosol Generator combined with Particle Measurement.

Aerosol generators

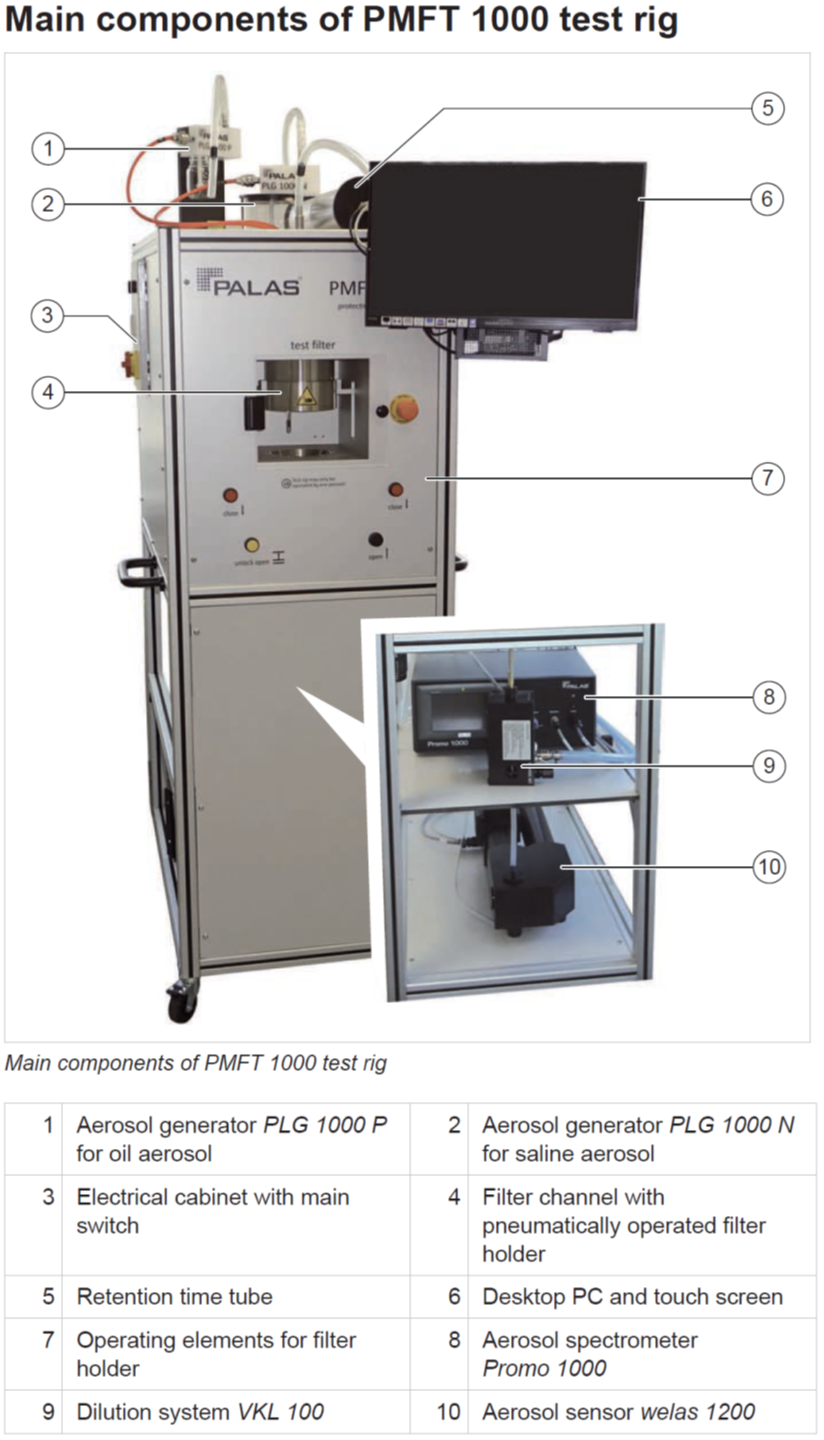

The aerosol is created by two aerosol generators. The aerosol generators are triggered by a solenoid valve and switched accordingly. The hose connection of the respective generator to the filter holder must be manually modified before changing the type of aerosol.

Salts (e.g. NaCL, KCl) and liquid aerosols (e.g. DEHS) can be dispersed.

Recommended concentration for saline aerosols: 5%.

Particle measuring technology

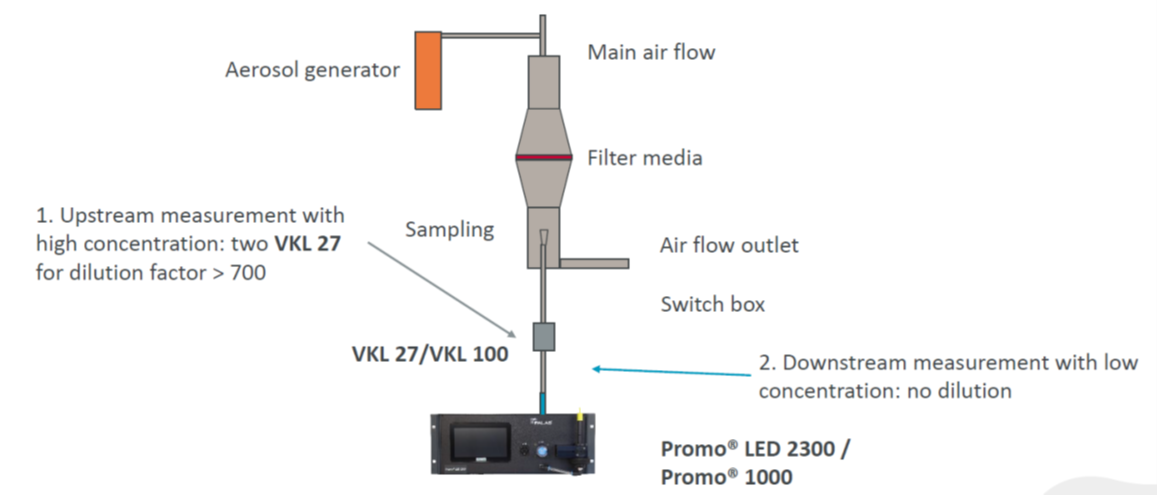

The test rig has an aerosol sampling unit on the clean gas side. An aerosol spectrometer with aerosol sensor is used to measure the particles.

The particle size and concentration are measured with and without the test filter to determine the fractional efficiency grade.

Volume flow control

The test rig has two flow controllers (mass flow controllers):

Mass flow controller 1 to control the main volume flow

Mass flow controller 2 to control the generator volume flow

Recording sensor data

The test rig has a sensor that measures differential pressure. The values measured at the filter are automatically recorded during filter testing.

The flow diagram shown below details the aerosol path through the filter media, then into the particle measurement device which confirms the mask or filter media efficiency. Masks are tested for efficiency when a person inhales and exhales. Meaning the aerosol is sent in both directions through the filter media.

Written by Jim Shorey, CD Nova, CRAZ member